We Alumina

ZIBO HONGHE CHEMICAL CO., LTD.

Get to know HONGHE CHEMICAL

2004: Our company began to specializing in the production, development and marketing of high purity alumina.

2009: The company renamed and registered as "HONGHE" Company.

2011 : We invested the construction of a new production base - Zibo Honghao Crystal Materials Co., Ltd. in Gaoqing County Economic and technological development zone, and put into production in the following year.

2022: The company has passed High-tech Enterprise Certification (China Torch Program).

2023: The company became a SRDI Enterprise of Shandong Province.HONGHE CHEMICAL has been focusing on high purity alumina as well series of its products. By virtue of its chemical stability, high melting point, high mechanical strength, high hardness, good thermal conductivity, high insulation and other properties, our high purity alumina can meet requirements on electronic materials, technical ceramics, precision polishing, functional additives, catalyst, spraying materials, semiconductor materials and crystal materials and other high-quality applications, and its future application prospects are even more sustainable.

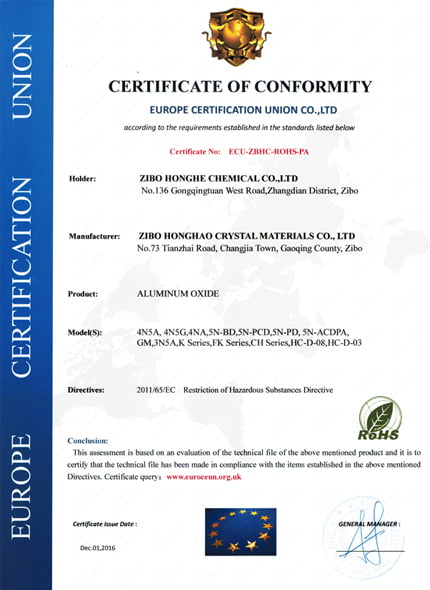

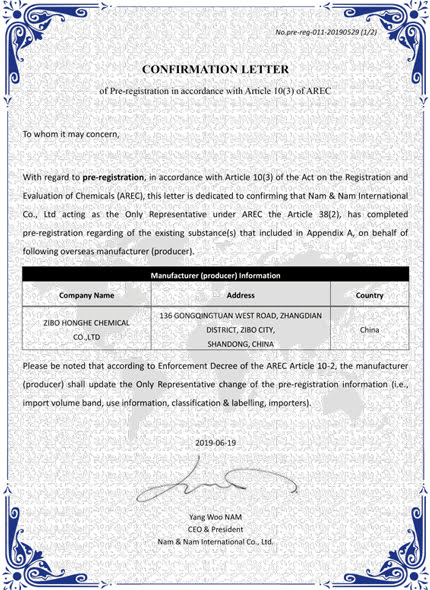

The company has passed High-tech Enterprise Certification, Provincial SRDI Enterprise Certification, Enterprise Credit AAA Certification, ISO9001-2015 Quality System Certification and ISO14001-2015 Environmental System Certification, ISO45001 Occupational Health and Safety Management System, European Union REACH Certification and the European Union ROHS Certification, as well as the Korea REACH Certification.

At present, the company has 3 invention patents and 17 utility model patents. We are also participating in the development of a national standard. We will continue to meet market demand through excellent service, innovation and stable quality.

Technical Advantages

1. The product quality is stable and the expected quality difference is small.

2. Except for Si and Na, the high-purity alumina powder is less than 1ppm. For pellet, granules and etc., these 2 elements are also less than 2ppm.

3. The high-purity alumina ALPHA and GAMMA powders produced by this process have excellent flow properties and can be used for downstream production operations and compatibility.

4. Compared with other processes such as the aluminum alcohol method, this process has the lowest production cost.

Corporate Culture

2. Philosophy: pursue excellence and achieve the future.

3. Principle: honesty and dedication.

The company adheres to the use of advanced equipment, purchase of appropriate raw materials, use of advanced technology to manufacture products with stable quality, and is committed to becoming a high-end, professional industrial powder material production plant.

Quality Assurance